Are you maximizing the value of your Employee Supply Chain? Three ways to increase your team’s worth by the end of the week.

Former business school students, pop quiz – what’s the definition of a supply chain in an organization? One source talks about supply chain as the system that facilitates the flow (of products, services) through the business. Another explains that managing the supply chain is a must- have because “an optimized supply chain results in lower costs and a faster production cycle”. It includes all of the steps to get it from the producer to the customer.

Have you ever thought of your team as having their own supply chain? If so – knowingly or not, you have worked on your company’s Employee Supply Chain.

Definition: Employee Supply Chain– the end to end operational process of an employee’s impact on an organization:

- Acquiring – (producer) Stage of hiring decision, intake, onboarding/orientation

- Developing – Stage of skills training, performance management, and leadership development (transit, in-process)

- Retaining/Exiting – promotion, actualized leadership, and outplacement (retirement, attrition)

An optimized Employee Supply Chain (ESC) blends operation and HR tactics to maximize employee’s talent engagement, capacity & productivity. An optimized ESC strategically & strategically reduces uncertainty for an organization in employee expenses.

The goal is to optimize your Employee Supply Chain and maximize the value for one of your top organization expenses – your employees. It is a process for recognizing that support in a certain area, the decision to hire, the hiring process, the onboarding process… and then the development, growth, and evolution through the organization’s cycles – reviews and moves, and at some point – either promotion or attrition, to complete the chain, could make the difference in a bottom line by reducing overall expenses by 5-10% or more.

Anyone that has a hand in ANY part of Employee Supply Chain (ESC) as described above – has the ability to grow, influence and enhance the strength of their own Employee Supply Chain.

Business Dictionary notes that producers at the beginning of the supply chain (in the case of ESC, the initial decisions made by CFO’s, CEO’s, CHRO’s and hiring managers of the employee process) can only compete through the supply chain. Unless the rest of the supply chain improves, “no degree of improvement at the producer’s end” can make up the problems downstream in the supply chain.

So… that means – if you own:

- Initial Decision to hire (capacity, organization need)

- Hiring process (recruiting, interviewing)

- Onboarding Process

- Job Functionality (training, teamwork, interaction)

- Job Process (development, growth, and evolution through reviews, transfers)

- End of Job-Life (promotion, retirement, attrition)

… you have ownership of part of your organization’s Employee Supply Chain.

How optimized is your own team’s Employee Supply Chain? Let’s briefly take a look.

- Ineffectiveness –

The graph above demonstrates how wasted costs is associated with being ineffective in your Employee Supply Chain. Having more employees than you need. You hired 5 people, yet you really only needed 3 people…. But didn’t realize that until 6 months later. Perhaps you weren’t equipped with the understanding of the capacity of the individuals – or the job. Perhaps you followed an example of a model that did not match with your business. Ineffectiveness is having wasted costs due to more employees than the organization needs in the business.

Potential outcomes… Employees in this group could be underutilized, overutilized undertrained and could have a sense of loss meaning/ understanding of their place in the company

Ask yourself…. How can you determine if you’ve hired effectively? What can you do to help to reduce ineffectiveness in the future?

-

The diagram above exhibits the role inaccuracy plays in the Employee Supply Chain. Hiring at an inaccurate moment leads to wasted time/costs. Inaccuracy – Accuracy deals with timing – which can be everything. You know you will need to hire a business analyst to help shoulder some of the work – so you hire in Q1… but realize later that two other employees had the ability to do the work, at least until Q3. As a result, Inaccuracy and wasted time/ costs evolved you hired earlier than needed, as you could have delayed the hires, reducing employee expenses for the year.

Potential outcomes… Employees in this group may also feel underutilized if hired too early, or overutilized if hired too late (“you need me to do too much at once, I don’t understand!”). They may feel like a “5th wheel” and a lack of connection to the company.

Ask yourself…. “What is the capacity of my team that I already have? How much do I know about the job needs that I’m hiring?”

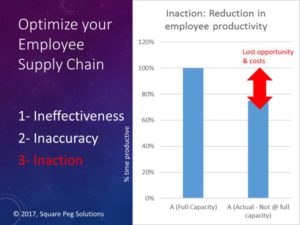

- Inaction – Whereas the first two elements of loss in the Employee Supply deal with the hiring itself, the final one deals with the results when those have happened

As you can see above. When employees are not working at full capacity, there can be severe lost opportunities and costs. , or if the employee loses the drive to complete the job. Typically, an employee initially begins a job with 100% effort – once (s)he is trained, they perform (or generally want to) at 100%. Over time, due to many reasons (manager, lack of motivation, engagement, etc.), this effort decreases, resulting in a 70% or 80% output (productivity). Multiple this by a number of employees… and you suddenly find yourself with much less employee productivity… and paying the same price in employee expenses!

Potential outcomes… Employees in this group feel disengaged, unproductive – and may or may not know it. They tend to have multiple strengths or talents that are not being utilized and may be considered siloed into their current job instead of being able to contribute in other areas of their work.

Ask yourself “At what capacity do I think my team is? If they are not 100%, do I know why? Can we help them?”

How are you maximizing your employee supply chain? Share this… and share your story.

In additional news:

- Last month, I asked you how to “make” it as a manager. Thank you to the many of you that contributed and congrats to Curt from Dallas TX on his $25 Amazon gift card! Be on the lookout for the summary and results in upcoming months! Thank you!